High-precision levelling operations are important for modern site construction requirements because accuracy is paramount and time is of the essence. Designed for excavation and other construction-related activities where precision is required, 3D and GPS machine control technology delivers.

Backed by our skills, innovation and cutting-edge systems, our approach ensures excellent outcomes for our clients while reducing costs and environmental impact. We do it right the first time with machine control technology.

New technology for better results

Traditionally, levelling operations relied on manual methods or basic levelling equipment, which were time-consuming and prone to human error. With advanced technology, particularly 3D and GPS machine control technology, the construction processes have been transformed.

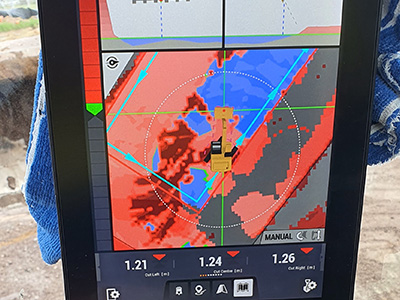

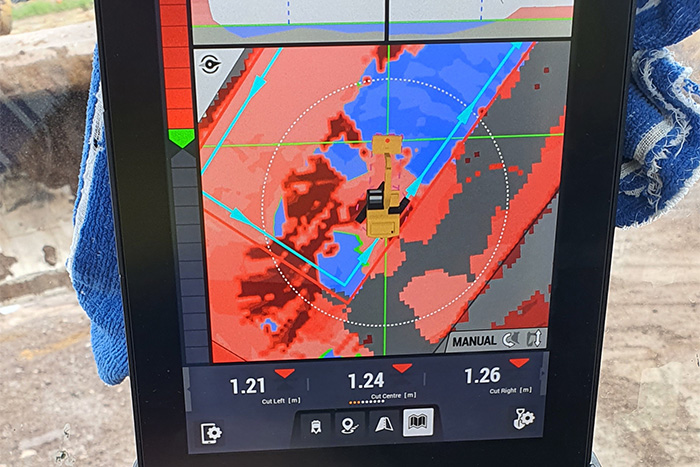

Time is money, which is why we utilise Trimble GPS Machine Control and 3D/GPS Surveying to be more efficient and productive. With high-performance and accurate system applications, our operators to create smooth, flat or sloped surfaces with ease.

Our systems include:

- Trimble GPS Machine Control

- 3D / GPS Surveying

- Trimble Base Station Available

- Machine Control Expert Operator

The right solution for every project

Having integrated the latest technology into our control systems and the 3D / GPS Machine Control that is available on our 17.5 tonne Excavator have allowed us to achieve huge gains in earthmoving productivity, accuracy and speed. Adding the design into the software means painless, pegless, precise performance.

Speeding up the construction progress of the earthworks, works are carried out many times more precisely than without machine control and, depending on the system, the results are fully documented and can be integrated directly into the further process workflow and planning.

Key benefits of integrated 3D control automatics

- Trimble Earthworks machine control & Base Station

- Get real time depth, distance and slope information

- Roll a more efficient pattern

- Get an exact reference between the position of the blade and the target grade

- The best sensor technology allows for faster digging, dramatically increasing productivity

Automation means we can check or survey a site without the need for stakes in the ground. Machine Control Technology uses information to cut, fill or dig to a profile that exactly matches the X-Y-Z coordinates on a digital topographic plan. This eliminates most of the survey staking that a site needs, and the wait times that often accompany resurveys.